210D 5mm ripstop RPET fabric for bags and apparel Chinese manufacturer

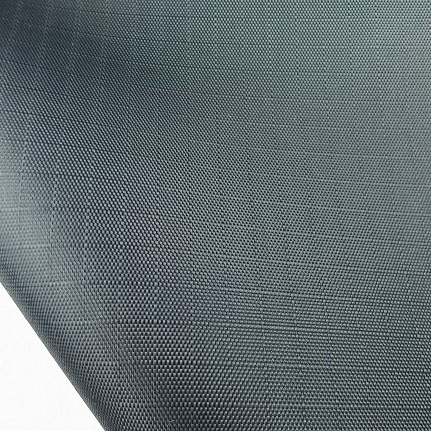

IGO textile is a 210D 5mm ripstop RPET fabric for bags and apparel Chinese manufacturer. As one kind of our fabric, the material of 210D 5mm ripstop RPET fabric is polyester, the composition is 100% RPET , the colour is black or tailor-made dyed, and the treatments is PU coating one time. We are specialized and professional in eco-friendly materials and dedicated to upgrade your products with sustainable and green fashion. We will help you develop your market by the leading edge of applying latest green materials on your products.

Delivery: EXW, FOB, CFR, CIF

Minimum order quantity: 2000 yards

Supply Ability: 100,000 yards / Month

Country of Origin: CHINA

Payment term: by T/T 30% as deposit, 70% before shipment

Lead Time: 30 Days

210D 5mm ripstop RPET fabric for bags and apparel Chinese manufacturer

We are a RPET fabric supplier in China,our Values is: Eco-consciousness, Integrity, Creativeness, Win-win. 210D 5mm ripstop RPET fabric as one kind of our fabric, the material is polyester, the composition is 100% RPET , good wind resistance,PU coating can play a waterproof role, feel plump and comfortable,wear resistance, moisture resistance, dry cleaning resistance, good strength, very suitable for bags, backpack and apparel, also suitable for home textiles, we has been GRS certificated and dedicated to upgrade your products with sustainable and green fashion,Transaction Certificate (TC) available when order, welcome to contact us to disscuss more.

Model no. : HYR-D650 Material : Polyester Composition : 100% RPET Specifications : 210D Colour : black or tailor-made dyed Treatments : PU coating one time Features : 210D 5mm ripstop, 100% RPET, 210D 5mm ripstop RPET fabric Width : 150cm GRS certificate : Transaction Certificate (TC) available when order

Fabric is the main material of bag and case

Fabric is the main material of bag and case, which not only directly affects the appearance of the product, but also relates to the market price of the product, so great attention must be paid to the design and selection. Design modelling, material and colour are three elements of design.

The color and material of the bag and case are directly reflected by the fabric, and the style and shape of the case depends on the softness, crisp and thickness of the material to ensure.

There are many kinds of materials that can be used for the fabric of luggage products, and the products are classified according to the different fabrics, such as: real leather bags, imitation leather bags, plastic boxes, plush bags, cloth handbags and so on.Each bag fabric has its characteristics, depending on your use, where to use, suitable for their own is the best.

What are the common finishing processes for fabrics?

1.Make the fabric door width neat and the size and shape stable. Belong to this kind of finishing, shrinkproof, wrinkle-proof and thermal setting, known as setting finishing.

2.Improve fabric feel. If stiff finish, soft finish and so on. Such finishing can be done by mechanical, chemical or a combination of the two.

3.Improve fabric appearance. Such as gloss, whiteness, drape and so on. There are calendering finish, whitening finish and other finishing to improve the surface properties of the fabric.

4.Other performance improvement. Such as cotton fabric flame retardant, water repellent, sanitary finishing; Chemical fiber fabric hydrophilic, anti – static, anti – pilling finishing.