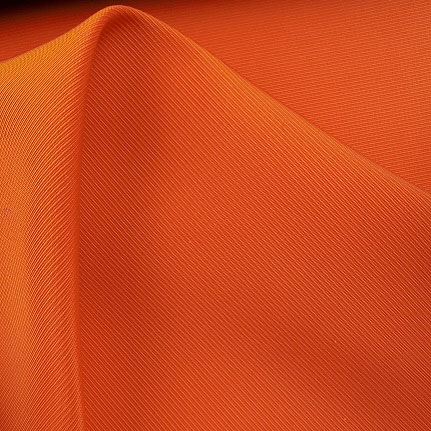

75Dx75D+300D anti-wrinkle and water resistant RPET poliester fabric in tangerine color

IGO textile is a 75Dx75D+300D anti-wrinkle and water resistant RPET polyester fabric in tangerine color manufacturer in China. The Material of this kind fabric is polyester, the composition is 75D*75D+300D Memory like fabric, the colour is Orangered or tailor-made dyed, the specifications is 100% RPET and the treatments is waterproof. As a RPET polyester fabric supplier ,our mission is to help set up an eco-friendly lifestyle throughout the world.We are specialized and professional in eco-friendly materials and dedicated to upgrade your products with sustainable and green fashion.

Delivery: EXW, FOB, CFR, CIF

Minimum order quantity: 2000 yards

Supply Ability: 100,000 yards / Month

Country of Origin: CHINA

Payment term: by T/T 30% as deposit, 70% before shipment

Lead Time: 30 Days

75Dx75D+300D anti-wrinkle and water resistant RPET poliester fabric in tangerine color manufacturer

IGO textile is a professional recycled PET polyester fabric manufacturer in China. The Material of 75Dx75D+300D anti-wrinkle and water resistant RPET poliester fabric in tangerine color is polyester, the composition is 75D*75D+300D Memory like fabric, the colour is Orangered or tailor-made dyed, the specifications is 100% RPET. The treatments is waterproof. The surface of this fabric has clear lines, bright beautiful color, the thickness is moderate, handle sofe, have good air permeability and moisture absorption,firm and durable, not easy to deform ect. Can be used for a variety of clothing and household items and so on. Transaction Certificate (TC) available when order, welcome to contact us to discuss more.

Name : 75Dx75D+300D anti-wrinkle and water resistant RPET poliester fabric in tangerine color Model no. : HYR2287 Material : polyester Composition : 75D*75D+300D Memory like fabric Specifications : 100% RPET Colour : Orangered or tailor-made dyed Treatments : waterproof Features : anti-wrinkle fabric,anti-wrinkle RPET fabric,75Dx75D anti-wrinkle RPET fabric for bags and apparel Width : 150cm GRS certificate : Transaction Certificate (TC) available when order

The main functions of water resistant are: water resistant, moisture permeability, breathable, insulation, windproof and so on.

The main functions of water resistant are: water resistant, moisture permeability, breathable, insulation, windproof and so on. From the production process, water resistant breathable fabric technical requirements are much higher than the general waterproof fabric; At the same time, from the quality point of view, waterproof breathable fabric also has the functional characteristics that other waterproof fabric does not have. The water resistant breathable fabric not only strengthens the air tightness and water tightness of the fabric, but also has the unique breathable property, which can make the water vapor inside the structure discharged quickly, avoid the structure to breed mold, and keep the human body dry all the time. It perfectly solves the problems of breathable and windproof, waterproof and warm, etc. It is a new type of healthy and environmentally friendly fabric.

The processing process of cloth is divided into detailed steps:

1.Drawling: the chemical fiber pulls out the yarn through the process and determines the thickness of the sample yarn. The factory generally buys the yarn cake directly (this process is not completed in the factory);

2.Warping: concentrate the scattered yarn cakes on the cobblehead, the number of cobblehead is related to the yarn grain;

3.Combining yarn: combine two or more coiling yarns into one coiling yarns, for example, 600D yarn can be made by combining two 300D yarns;

4.Sizing: sizing water after yarn and make yarn stronger;

5.Warp parting: the warp yarn is staggered up and down by the machine so that the filling yarn can pass through;

6.Weaving: there are two kinds of knitted fabric and tatting;

7.Finalize the design: the cloth is made of embryo cloth after weaving, and then finalize the cloth by high temperature drying and finalize the cloth;

8.Bleaching and dyeing: dyeing cloth, dyeing according to customer needs, it needs to be noted that the current domestic bleaching and dyeing technology, there will be color difference in each cylinder of the cloth, the industry has become the cylinder difference, this is because of the dyeing material in the deployment, temperature control, dyeing time and other differences;

9.Post-cleaning: post-processing of the dyed cloth to meet the special needs of the cloth.