What is recycled polyester?

Recycled polyester is a new type of environmentally friendly recycled material. Its source is low carbon, creating a new concept in the field of regeneration.

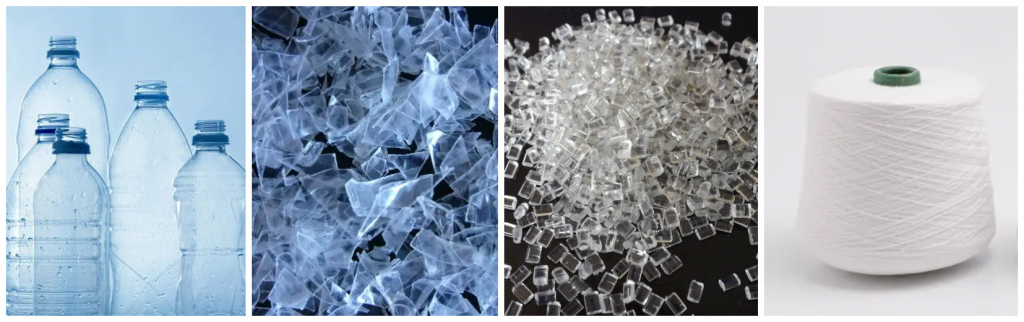

At present, recycled pet bottles (plastic bottles) can be made into fragments after treatment, and recycled fiber can be made into recycled polyester yarn through the spinning process after granulation and melting and drawing. The fabric made from recycled polyester yarn is called recycled polyester fabric. 100% of recycled polyester materials can be recycled into PET fiber, effectively reduce waste, effectively reduce carbon dioxide emissions, energy saving nearly 80% compared with conventional polyester fiber production process. Recycling fiber subverts traditional raw material sources, comprehensively utilizes waste resources, and endows fiber with “second life”. At the same time, the performance of recycled polyester is comparable to and in some cases superior to that of native polyester.

Recycled polyester produces less pollution than primary polyester. According to the statistics of SRIC, in the polyester industry of the United States, from petroleum processing to PET polyester, every 1 ton of PET polyester produced produces 1.871 tons of CO2, and recycling 1 ton of recycled PET polyester to make polyester can effectively avoid this part of CO2 emissions. If the recycled waste PET polyester increased to 10 million tons a year, is at least a year can reduce 18.71 million tons of CO2 emissions, in the aspect of reducing carbon emissions is equivalent to an increase of 660000 hectares of forest. Recycled polyester industry development can significantly reduce pollution emissions, help to solve the problem of regional environmental degradation, is beneficial to the human society sustainable development for a long time.

Transform PET bottles into recycled polyester

PET bottles are the most common disposable plastic bottles. Polyester is made from polyethylene terephthalate (PET), which is the same material as PET bottles, a type of polyester that is widely used in the textile and packaging industries.

If the waste plastic bottles around us are thrown away conveniently, it is the garbage that pollutes the environment, but if it is recycled, it may become a fluffy toy, a coat, a backpack, an umbrella or a set of car interiors. With waste textiles, coke bottles and waste drinking water bottles as the initial raw materials. Recycled polyester staple fibers are finally formed through more than ten processes such as sorting, cleaning, drying, melting and spinning. These polyester staple fibers can be used as filter materials, as well as internal fillers for car interiors, sofas, cushions, pillows and bedding products, achieving both economic and social benefits. Recycled polyester promotes the development of textile industry in the direction of green, low-carbon and recyclable.

The data shows that every ton of recycled products can reduce 6 tons of oil consumption and 3.2 tons of carbon dioxide emissions, equivalent to the amount of carbon dioxide absorbed by 200 trees in a day. The fiber converted from 5 2L PET bottles is enough to weave a large T-shirt, 20 500ml PET bottles can be used to make a winter coat, 35 2L PET bottles can be used to make all the filling fibers for a sleeping bag, and 40 2L PET bottles can be used to produce 1m2 carpet. In addition, 1 ton of waste PET bottles can produce about 0.9 tons of recycled polyester fiber, saving 1.5 tons of oil and 3 cubic meters of landfill space. These figures are beyond everyone’s imagination. The small PET bottle, after becoming fiber, can bring such great changes to the whole earth and the whole society. The rapid development of the polyester industry has brought an attractive recycled polyester market and added new colors to the circular economy of the textile industry. Environmental protection fashion is spreading from Europe and America to the world. Recycled polyester fabric is not only beautiful, but also a brand-new and healthy outlook on life and fashion, which is very consistent with the concept of European and American brands. Therefore, it is widely popular abroad, especially in Europe and America.

The Steps of transforming PET bottle into recycled polyester

(1) Cleaning

Clean the bottle first to separate the bottle body from the bottle cap; then soak it in caustic soda to let the label on the plastic sheet fall off. After two times of cleaning, the plastic sheet becomes very clean, which can meet the requirements of subsequent fiber making.

(2) Smash

Recyclable plastic bottles are collected and crushed, transported to the processing plant, separated from transparent plastic and colored plastic, and then crushed by the plastic crushing production line.

Crushing treatment is one of the indispensable steps in the process of plastic transformation into textiles. Plastic bottles are various and of different sizes. It is necessary to break them into small pieces of certain size before further recycling.

(3) Heat melt and wire drawing

During spinning, firstly, the moisture of the plastic sheet is fully dried, and then it is melted at 270 ℃, extruded by a screw extruder and cooled into filaments (generally including staple fibers and filaments).

Short fibers can enter the weaving process after spinning / filament deformation and other processing. Weaving methods are generally divided into machine weaving and knitting.

(4) Dyeing and molding

After dyeing, finishing, molding and other processes, the fabric will become soft and can be used for clothing and life.

Through “deep cleaning” under high temperature, vacuum and other conditions, the recycled PET plastic has been able to reach the cleanliness level sufficient to produce food packaging. Now, the waste beverage bottles can be recycled into new beverage bottles, which can be said to realize “recycling”.

Why recycled polyester replaces polyester?

Sustainable development is a global development strategy in the 21st century. Paying attention to the environment and health, vigorously developing circular economy and energy conservation and emission reduction have become the theme of the development of the whole international community. Recycled polyester fabric is the recycling and utilization of a large number of waste plastic products produced by People’s Daily consumption. It can effectively get rid of the excessive dependence on oil resources, reduce carbon dioxide emissions, protect the environment, reduce pollution, and play a good role in environmental protection and energy saving.

No one knows the true scale of plastic waste: “Some say it’s about the size of Quebec, or 600,000 square miles — also known as twice the size of Texas. Others say the debris swept up by ocean currents is the size of the United States – 3.8 million square miles. Or it could be twice that size.” No one seems to be able to agree on the size of plastic waste. Plastic can harm Marine birds and mammals that eat it because it carries toxic substances, punctures internal organs and tricks animals into thinking they’re full. Polyester (PET) is a major component of this waste because polyester is the main ingredient in beverage containers such as bottled water.

Secondly, polyester production is about 50 million tons per year, and the production consumption is about 104 million barrels of oil (this does not include the energy required for transportation). It also causes many environmental problems, which is why polyester is considered as a non eco-friendly textile.

In the past few years, the important challenges facing the polyester industry have been the awareness of environmental degradation and the growing demand for environmentally friendly products. Consumers are already demanding environmental labels that state how many grams of carbon dioxide, or equivalent greenhouse gas emissions, are produced during the production, transportation and storage of a product. In this case, recycled polyester came into being to minimize these problems and meet the needs of customers.

The advantages of recycled polyester:

- Keep plastic out of landfills and oceans – Recycled polyester gives a second life to a non-biodegradable material that would otherwise end up in landfills or oceans.

As for landfills, the United States Environmental Protection Agency reports that the country’s landfills received 26 million tons of plastic in 2015 alone. The European Union estimates that its members produce the same amount of carbon emissions each year. Compared with using not recycled polyester fibers, recycled PET bottle helps reduce the Marine ecosystem and the number of plastic garbage landfill, fabric, plastic can be converted to air, water and soil pollution is less, and helps to protect often threatened by plastic pollution of Marine ecosystem and underwater wildlife, thereby promoting the environment.

- According to a study by the Swiss Federal Environment Office in 2017, RPET is as good as the original polyester, but requires less resource to manufacture – the recycled polyester is almost the same in quality as the original polyester, but the energy required for its production is 59% less than the original polyester. Wrap estimates that the production of RPET can reduce carbon dioxide emissions by 32% compared with ordinary polyester.” In addition, recycled polyester helps reduce the exploitation of crude oil and natural gas to produce more plastics. The use of recycled polyester fiber can promote cooperation in the fashion industry and promote change. The website of outdoor brand Patagonia said:” the use of recycled polyester fiber reduces our dependence on oil as a source of raw materials.” The brand is famous for making wool from used water bottles, unusable manufacturing waste and worn clothes.” It limits waste, thus extending the life of landfills and reducing toxic emissions from waste incineration plants. It also helps promote a new recycling flow of polyester clothing that is no longer wearable,” the label added.

3, Through the production, processing and utilization of polyester waste materials, the recycled polyester fiber industry generates more social benefits than the economic benefits of enterprises. One is to put millions of people to work. Among them, recycling and cleaning industry alone solves about 450,000 jobs, recycled chemical fiber processing enterprises about 300,000 people, and recycled chemical fiber industry also directly drives about 800,000 jobs in related industries. The second is to save oil resources. The processing energy consumption of 6 tons of standard coal per ton of raw material can be saved by producing recycled polyester staple fiber from PET waste bottles compared with PET slices made from petroleum resources. Third, reduce white pollution, clean and beautify the environment, through the production and processing of waste, increase the effective supply of social products. At the same time, the development of recycled polyester fiber industry directly promotes and promotes the development of related industries (such as recycling, international trade, logistics, textile machinery, auxiliary materials, etc.).

Application and prospect of regenerated polyester staple fiber:

IGO Textile is an innovative company of eco-friendly fabric solutions, born in September 2005 with the DNA of environmental consciousness. Our company is specialized in eco-friendly materials and dedicated to upgrade your purchase with sustainable fashion and green products. We aim to help set up an eco-friendly lifestyle throughout the world. Our mission is to help set up an eco-friendly lifestyle throughout the world. Our Visions is to supply textiles made with eco-friendly and sustainable materials.

Polyester Staple Fiber is widely accepted by the market because of its low-carbon source and less waste in the production process. Compared with the traditional chemical fiber, the recycled polyester staple fiber has the characteristics of green, environmental protection and recyclable, which can effectively reduce carbon dioxide emissions and save nearly 80% energy compared with the production of conventional polyester fiber.

Recycled polyester is mainly used in cotton spinning industry, spinning alone or blended with cotton, viscose fiber, wool, hemp, etc. The yarn obtained is mainly used in textile and clothing, but also can be used in non-woven fabrics, filling materials, thermal materials, automotive interiors, civil engineering and other industries. Polyester staple fiber is mainly used in three fields: textile yarn, accounting for 77%, and the end products are clothing, home textile, decorative cloth, etc. Non-woven, accounting for 17%, the terminal products are wipes, masks, etc.; for filling, accounting for 6%. The terminal products are winter clothes, quilt pillows, toys, etc.

In terms of niche, recycled polyester can make blanket bottom wire, Oxford cloth, polyester FDY such over lock cloth, also can be used as imitation silk fabrics, and recycled polyester DTY can and cotton, wool, linen, chemical fiber blended, produces all kinds of knitted and woven fabrics, could be used to make jackets, casual wear, bed sheets, towels, socks and so on. Recycled polyester industrial filament is mainly used in tire cord, conveyor belt, canvas and so on. The recycled polyester staple fiber is mainly used in automobile interior decoration, shading products and toys, sofas and other filling fiber.

Today, green development has become a global consensus. As people pay more and more attention to environmental protection, green and environmentally friendly products have become one of the most important choices for consumers. Recycled polyester is used in satchels, bags, bags, socks, fashion bags, handbags, shopping bags and hats. Suspenders, shirts, skirts, children’s wear, scarves, cheongsam, ties, handkerchiefs, home textiles, curtains, pajamas, bows, gift bags, sleeves, fashion umbrellas, pillowcases, throw pillows shoes material, curtains and other uses.

Since 2010, Nike has used about 115 million renewable polyester bottles in its high-performance jerseys; NBA superstar Lebron James and England star Wayne Rooney both wear jerseys made from recycled polyester bottles; International famous luxury brands such as LV are also promoting the use of recycled materials.

It can be said that recycling fiber is a kind of fiber that leads the consumption trend and contains huge economic benefits. To realize efficient and low-cost recycling, we should start with the characteristics of waste, effectively combine the cost of recycling with the value of terminal products, and truly achieve value for money.

To realize a healthy circulation is of great significance to the sustainable development of both the plastic industry and the chemical fiber industry. As a service-oriented company, we focus on identifying, sourcing, and supplying eco-friendly products and services to targeted market segments. We will help you develop and expand your markets by the leading edge of applying eco-friendly materials on your new products. In the future, we will follow the development frontier of new technology and try our best to expand the application field of this fiber, leading the recycling of recycled fiber from the past simple, extensive nonwovens field to the current field of high-end products.

Recycled polyester meets Global Recycling Standard (GRS)

IGO Textile has been GRS certificated and dedicated to upgrade your products with sustainable and green fashion. Our recycled polyester is certified by GRS (Global Recycling Standard). GRS certification is a global recycling standard. GRS was originally formulated by the Dutch Regulatory Union and implemented in November 2008. It is a third-party certification standard established for the use of recycled fibers after recycling waste textiles. GRS certification includes five requirements: traceability, environmental protection, social responsibility, Label, and General principles.

GRS is suitable for any product that contains at least 20% recycled material. Starting with the recycling phase, each production phase must be certified and finally ends with the last seller in a business-to-business transaction. Material collection and collection sites are subject to self-declaration, document collection and site visit.

GRS certification is a voluntary, internationalization, and complete product standards and contents for manufacturers to product recovery, regulatory chain of supply chain control, recycled ingredients, social responsibility and environmental regulations, and limit the execution of the chemicals, GRS’s goal is to increase the use of recycled material in products, and to reduce/eliminate the harm caused by the production. GRS has been developed for the needs of the textile industry, verifying recycled products or certain products, and more importantly, allowing retailers and consumers to understand which parts of a particular product are recycled materials and how these materials are handled in the supply chain. The GOAL OF GRS IS to increase the use of recycled materials in products, and reduce the use of final products or semi-finished products containing recycled ingredients. The purpose of GRS is to call for the global protection of the ecological environment and the implementation of customized standards for sustainable development. At present, the certification mainly focuses on textile and garment enterprises, such as recycled bottle flake, recycled polyester filament, recycled polyester short thread, recycled fabric, recycled clothing, etc.